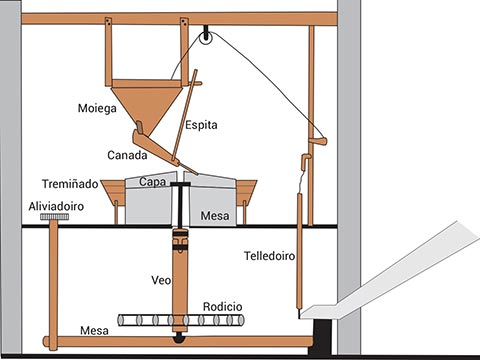

Mill and the fulling mill operation is very similar and have elements in common in their mechanical functioning. In both cases the force of the water grants movement to a gear wheel, called a rodicio. In the mills of Mosquetín, as in most of Galicia, these gear wheels are horizontal and turn the stones of the mills via a long vertical axis of wood. The elements of the machinery in contact with the water are located in the lower part of the building, an area that is often called the inferno (hell).

The rest of the machinery is housed inside. The most important pieces are the stones. The fixed and larger stone is called a mesa (table) or a pé (base) and this is placed a smaller—the cover or moa—which rotates through connection with the axis and wheel.

On the stones, hanging from the ceiling, we find the moiega, which is a space in the shape of an inverted cone in which the cereal is poured. The grain falls through the hole in the bottom of the moiega and passes a small wooden channel referred to as a canada that leads directly to the covering’s central aperture. Upon entering this hole, or eye, the cereal is crushed by the rotating movement of the cover and is converted into flour at the end of the two stones, finally falling into a wooden deposit box, or tremiñado. The fineness of the flour can be regulated according to the distance between the cover and the table. If you want a thicker flour, a thicker separation between the stones is needed and if you prefer finer flour, or munda, then the stones must be brought closer together. This operation is done through a piece called aliviaduira, which raises or lowers the wheel.